What is a good industrial packaging?

Here are 9 rules to follow when designing your packaging.

1.Protect

Packaging will protect parts against aggressions such as shocks, scratches and friction…

2.Compact

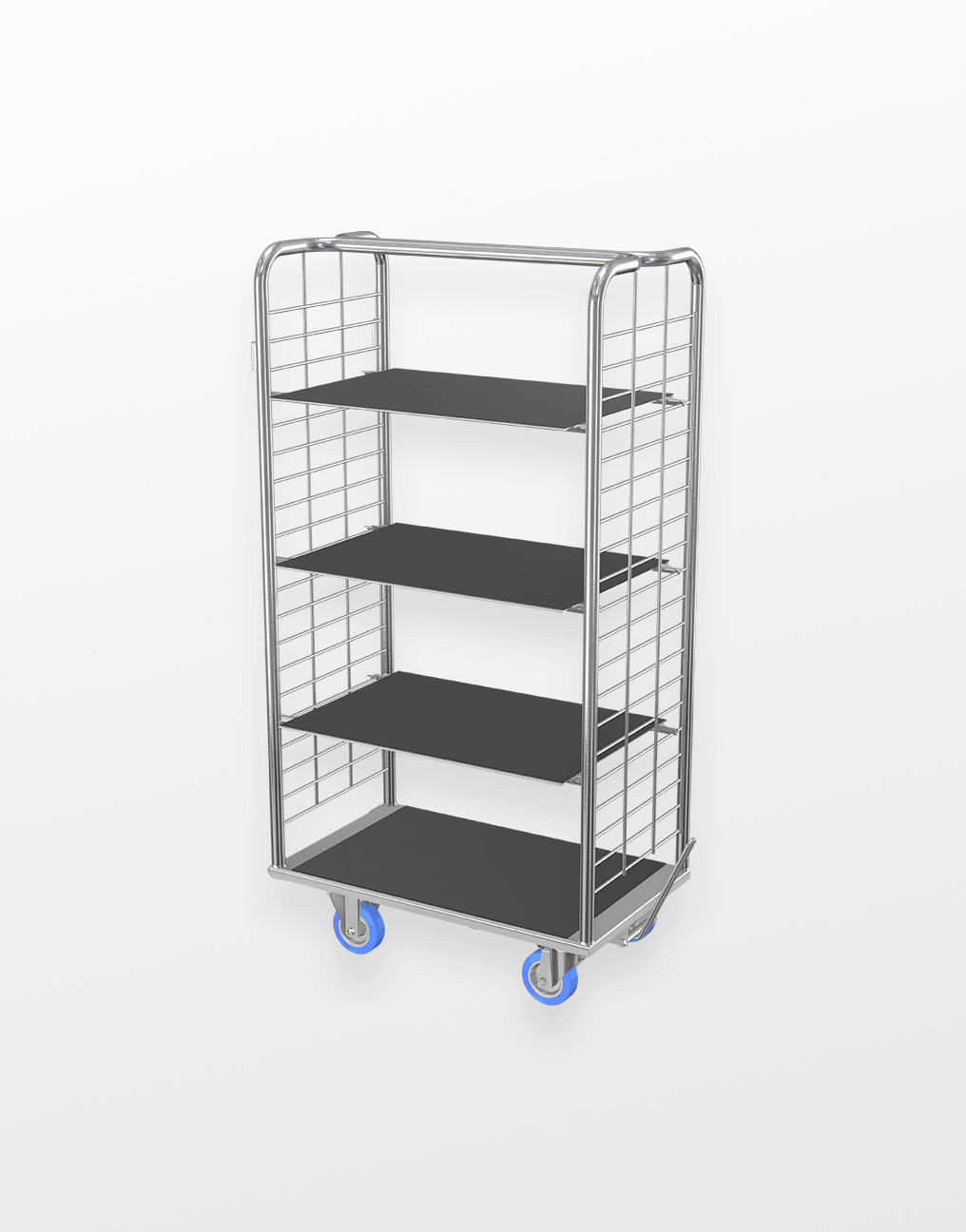

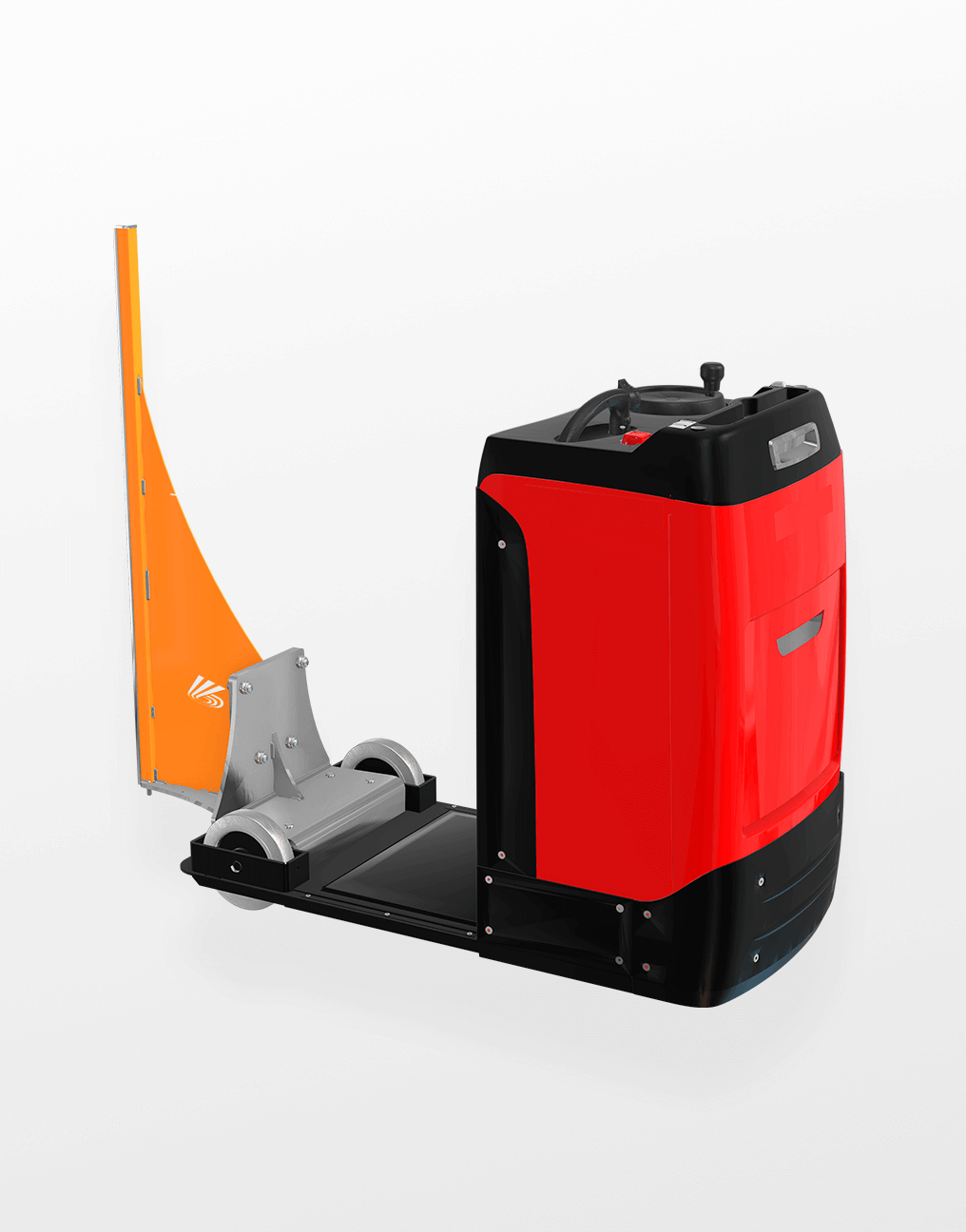

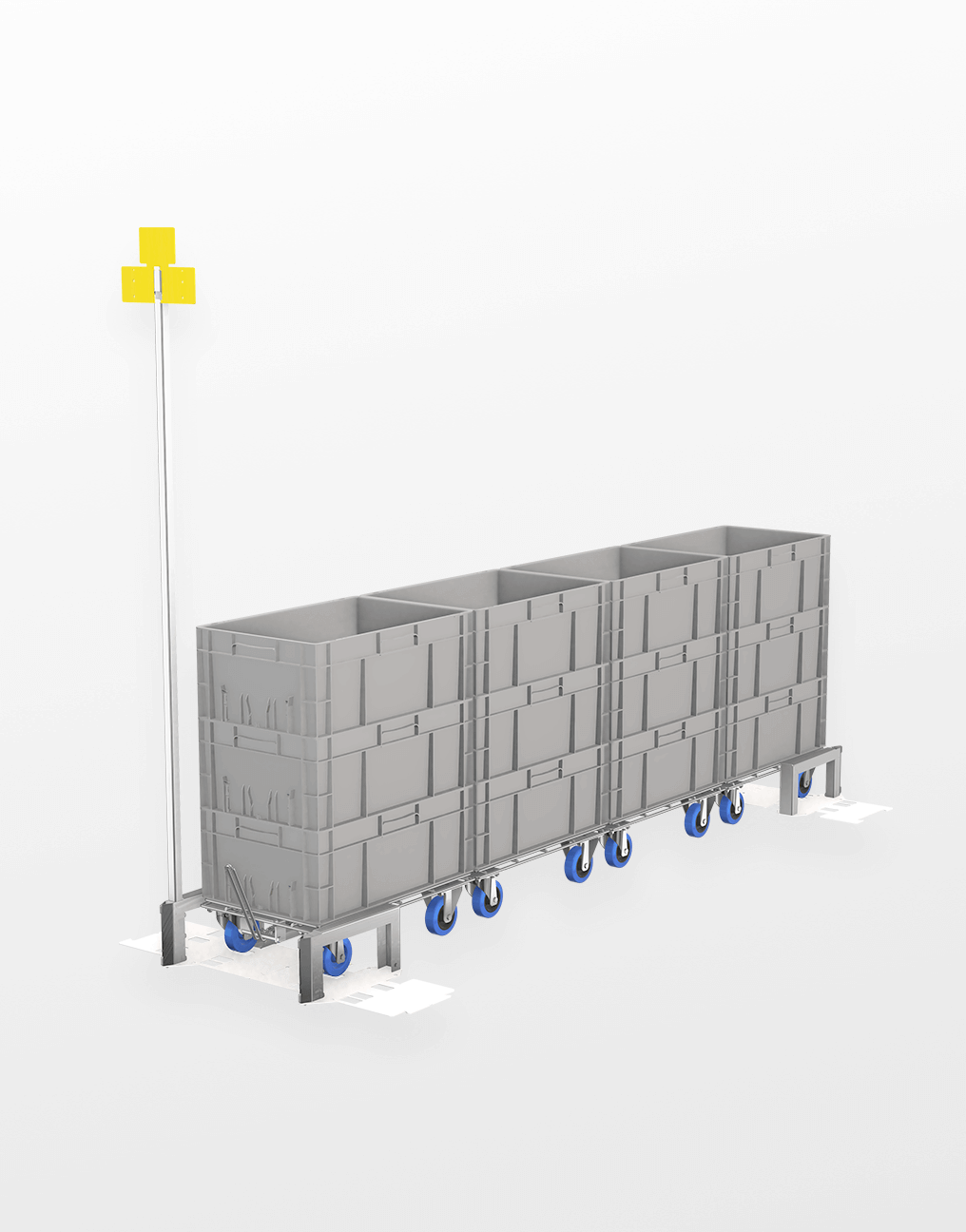

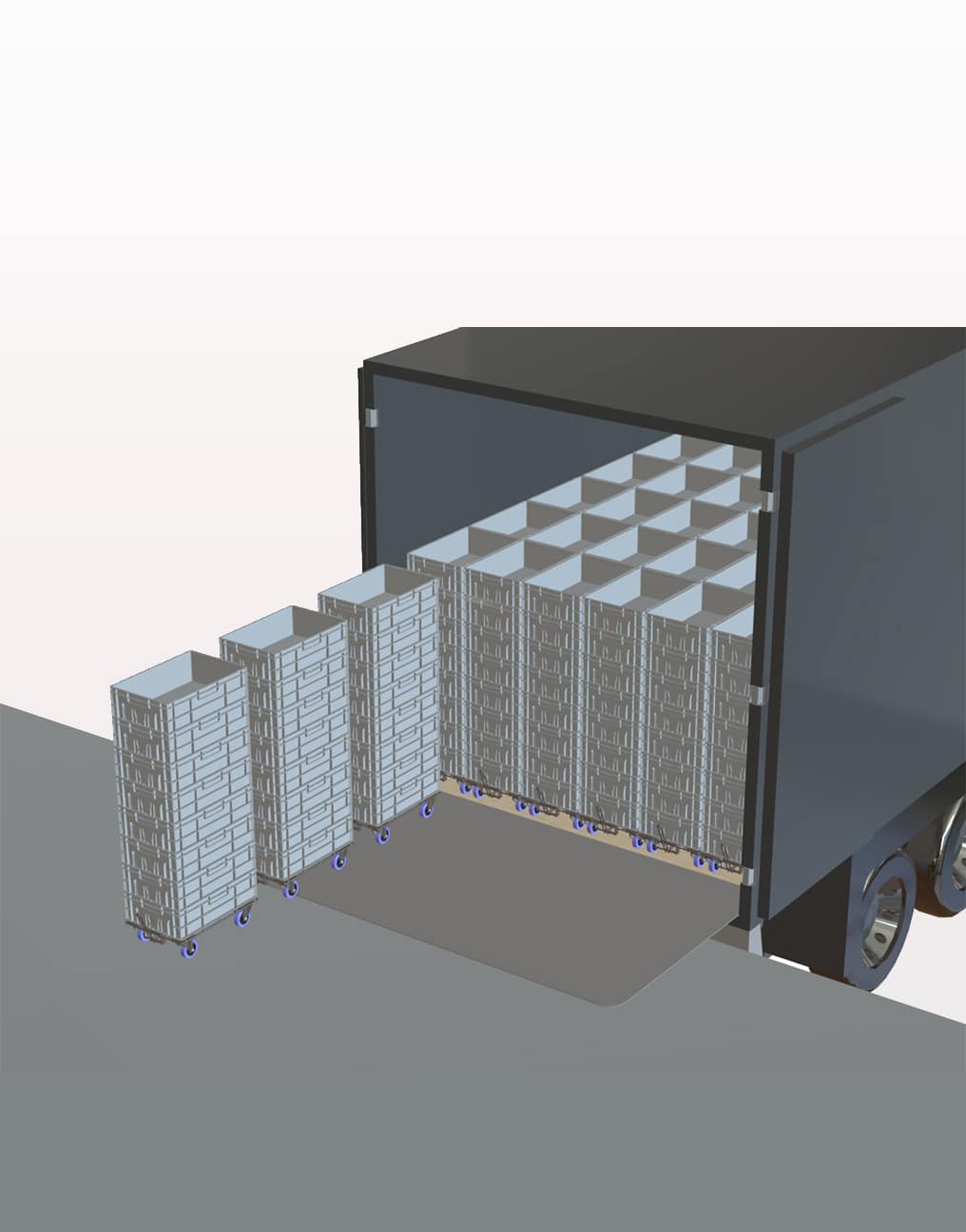

Choose your packaging according to the shape of the piece, not according to the quantity to be delivered. Package your pieces in the smallest possible container. The small pieces in containers and the large ones in handling Rollis trolley. Your packagings will be more compact and you will be able to position them as close as possible to the workstation or machine.

The quantity is processed through the number of packagings and the frequency of delivery.

3.Simple

This will increase the productivity of your operators and reduce the risk of shocks.

Looking for a complete lean solution?

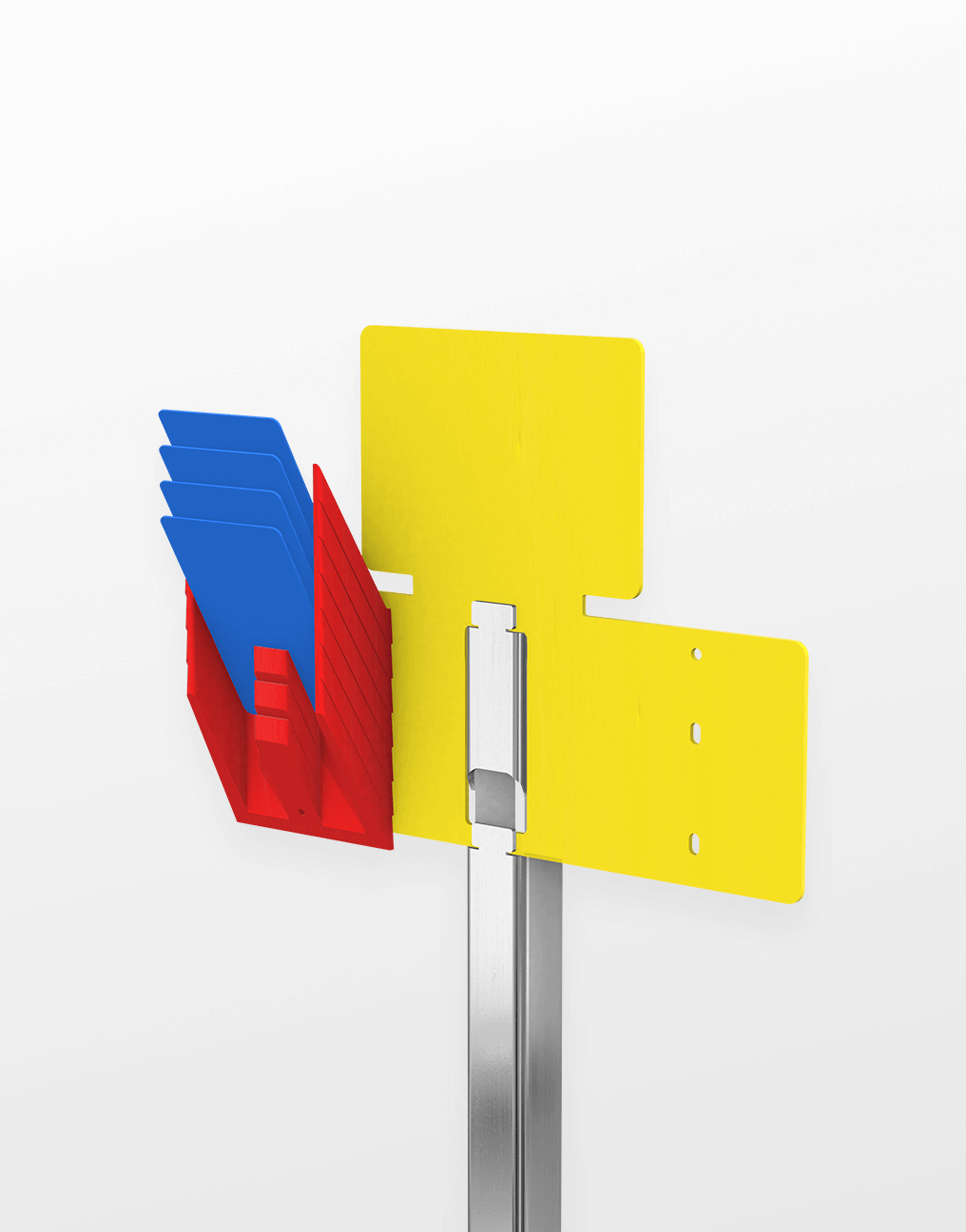

4.Obvious

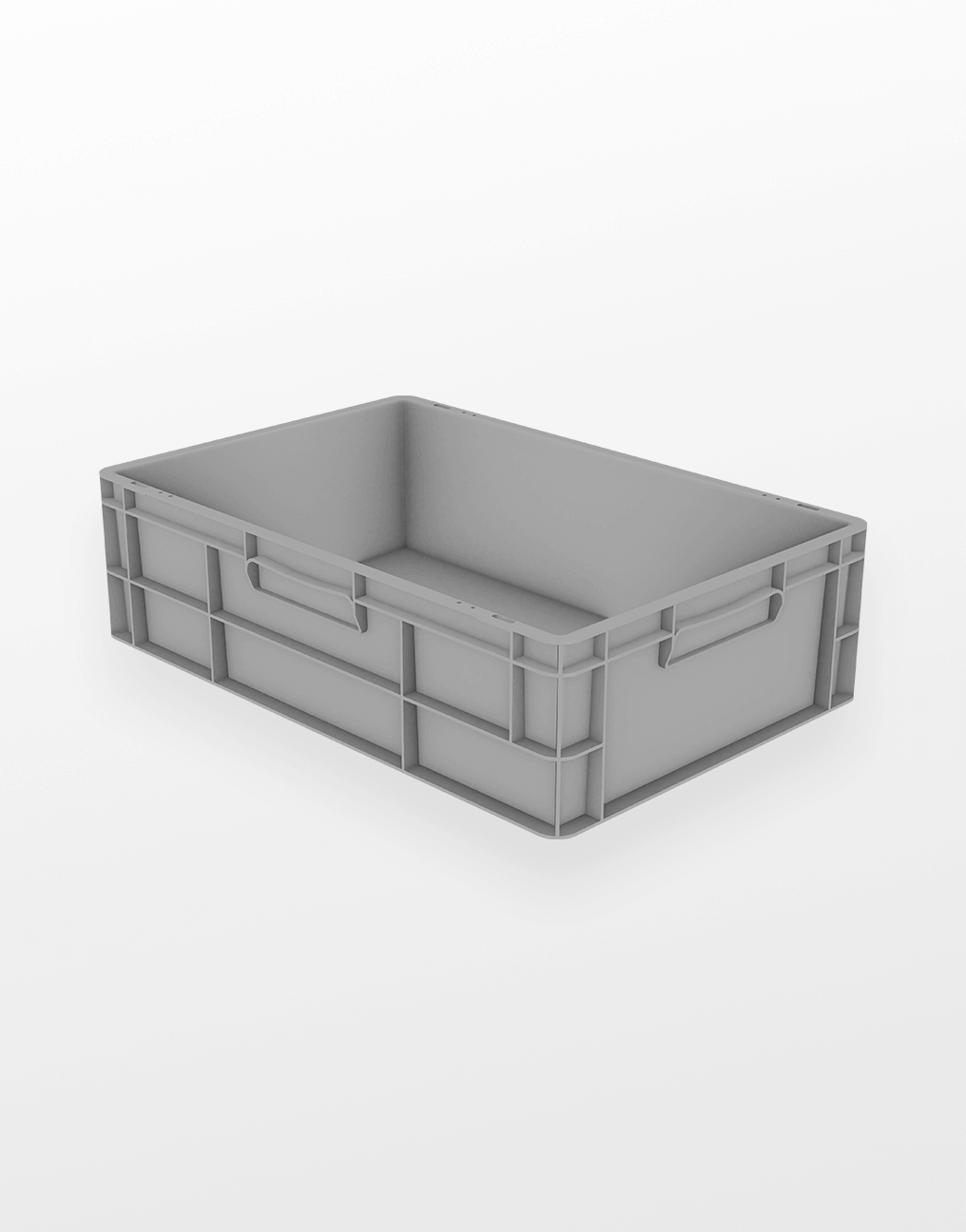

Put a single layer of products per packaging; Avoid high bins with dividers which increase the amount of packaging and clutter up the workstations. Choose a low bin with internal wedges.

5.Stable

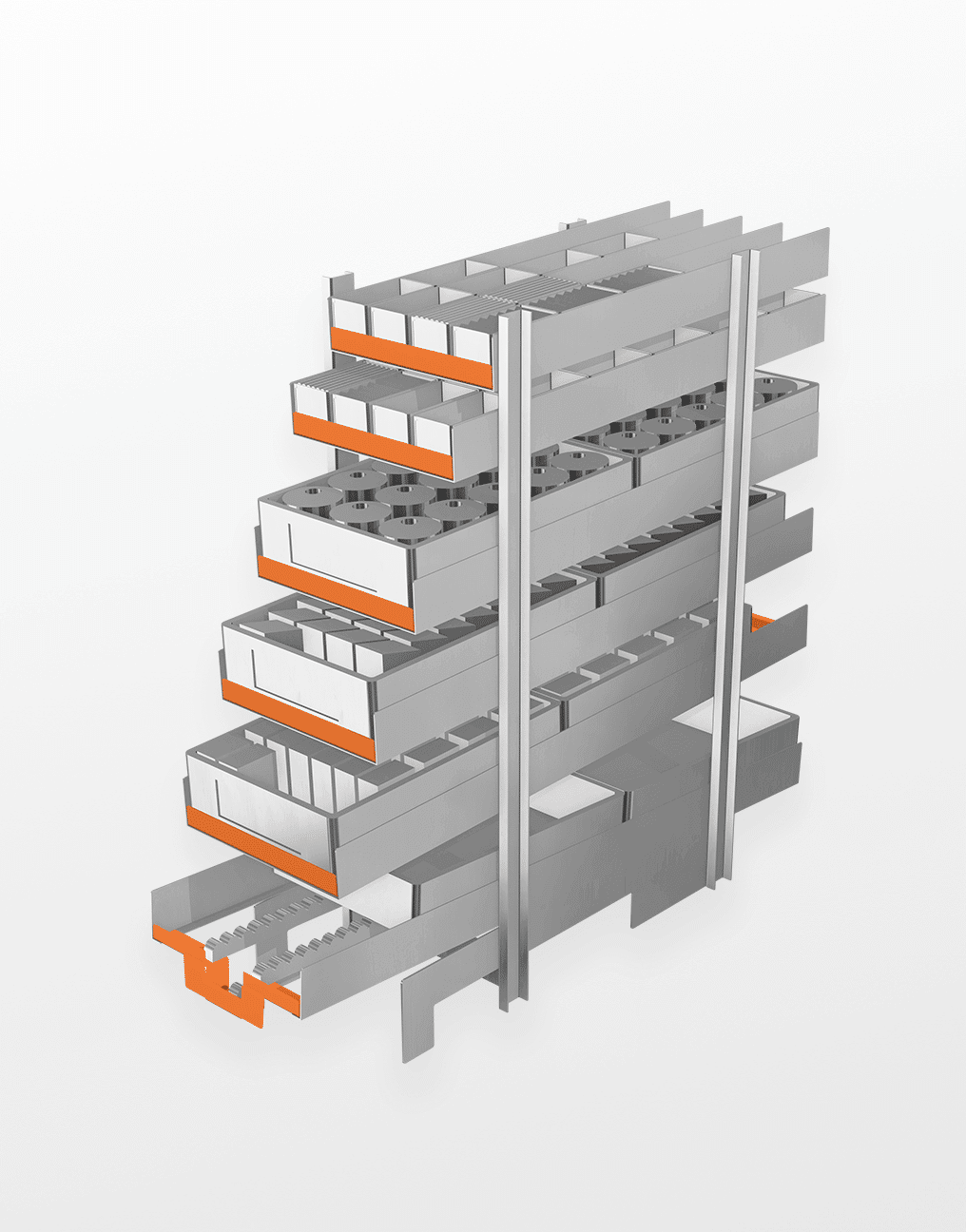

6.Versatile

Packaging for 4 different items

To do this research the common parts of your different pieces such as a bracket, a layer, a hole… You can use the same type of packaging to package different parts.

Such packaging will automate the filling easily.

7.Modular

For container packagings choose a dimension of 400, 300, 200 or 100.

Limit yourself to a minimum width of 100 mm to avoid MSD (musculoskeletal disorders) thanks to a grip without stress for the fingers.

8.Ergonomic

9.Sustainable

Packaging conception needs many decisions which optimization is sometimes complex. Labadis can coach you in the design and realization of your packagings.